Engineered for powder metallurgy, this high-temperature vacuum furnace ensures precise sintering and heat treatment for industrial components.

Achieves a maximum temperature of 1600°C, ideal for sintering cemented carbide, magnetic materials, and ceramic parts.

Features a high-performance vacuum system reaching up to 5x10-3 Pa, preventing oxidation and ensuring product purity.

Constructed with a multi-layer graphite felt or optional molybdenum sheet insulation structure for superior thermal uniformity.

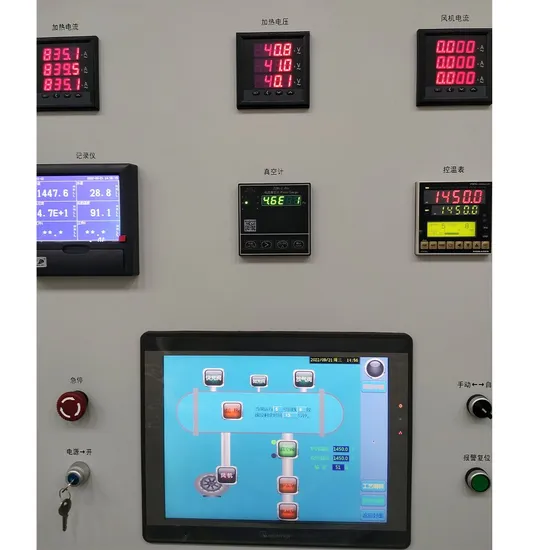

Equipped with a PLC-based computer control system for automated process management and consistent, repeatable results.

Offers customizable valid zone dimensions and dewaxing functions to meet specific production requirements.

Designed for robust industrial applications including aviation, military, automotive, and electronics manufacturing.

Maximum Temperature: 1600°C

Ultimate Vacuum: 5x10-3 Pa / 4x10-1 Pa

Heating Power: 80 - 450 kw

Loading Volume: 80 - 800 kg

Valid Zone (LxWxH): Customizable (e.g., 600x400x400mm)

Control System: Fully automated PLC computer control

We're here to help you with your needs. Let's talk about how we can help you.